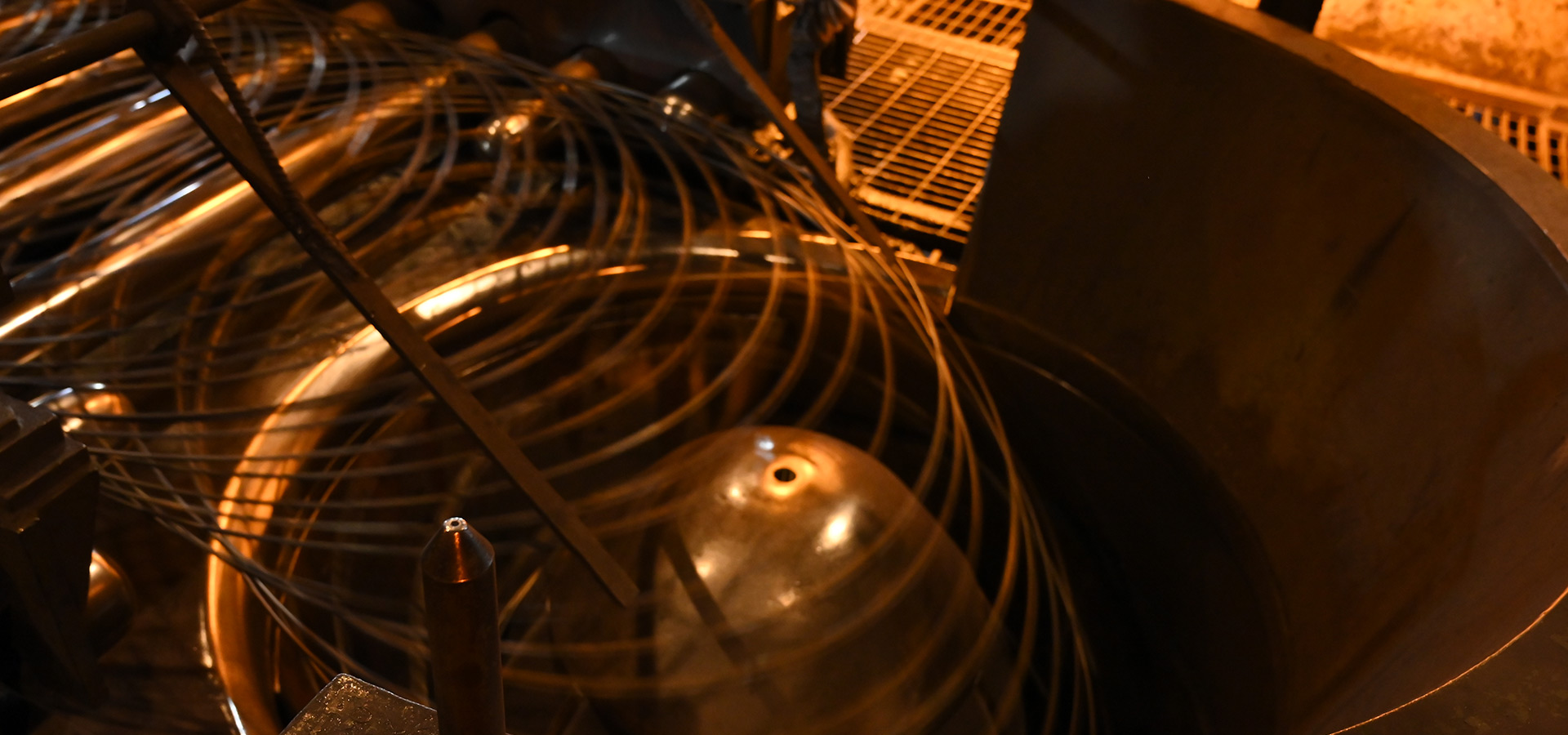

Wire rods are long, semi-finished steel products that are produced by hot rolling of billets and have various end uses and applications in the engineering, construction, power and automobile industry. The V-Wirro comes in low carbon, medium carbon and high carbon grades with a size ranging from 5.5mm to 16mm and meets the requirements of IS standards like IS7904:2018,IS7887:1992. Optimum controls in the steelmaking ensures clean steel and precise chemistry.The mill is equipped with advaced technology and helps in achieving uniform mechanical and metallurgical properties as well as excellent surface finish.

| Low Carbon Grades (5.5 to 16 mm Dia) | ||||||

|---|---|---|---|---|---|---|

| Grade | %C (Max) | %Mn | %P | %S (Max) | % Al | UTS (MPa) Max |

| IS 7887 Gr 2 | 0.08 max | 0.25 - 0.40 | 0.030 | 0.030 | 0.02 Min | 390 |

| IS 7887 Gr 3 | 0.10 max | 0.30 - 0.50 | 0.030 | 0.030 | 0.02 Min | 410 |

| IS 7887 Gr 4 | 0.08 - 0.13 | 0.30 - 0.60 | 0.030 | 0.030 | 0.02 Min | 430 |

| IS 7887 Gr 4M | 0.08 - 0.13 | 0.60 - 0.90 | 0.030 | 0.030 | 0.02 Min | 450 |

| IS 7887 Gr 5 | 0.10 - 0.15 | 0.30 - 0.60 | 0.030 | 0.030 | 0.02 Min | 450 |

| IS 7887 Gr 6 | 0.13 - 0.18 | 0.30 - 0.60 | 0.030 | 0.030 | 0.02 Min | 470 |

| IS 7887 Gr 7M | 0.15 - 0.20 | 0.60 - 0.90 | 0.030 | 0.030 | 0.02 Min | 510 |

| IS 7887 Gr 8 | 0.18 - 0.23 | 0.30 - 0.60 | 0.030 | 0.030 | 0.02 Min | 570 |

| IS 7887 Gr 8M | 0.18 - 0.23 | 0.70 - 0.90 | 0.030 | 0.030 | 0.02 Min | 600 |

| IS 7887 Gr 10 | 0.22 - 0.28 | 0.30 - 0.60 | 0.030 | 0.030 | 0.02 Min | 600 |

| Grade | %C (Max) | %Mn | %P | %S (Max) | % Al | UTS (MPa) Max |

| SAE 1006 | 0.08 max | 0.25 - 0.40 | 0.030 | 0.030 | 0.02 Min | 390 |

| SAE 1008 | 0.10 max | 0.30 - 0.50 | 0.030 | 0.030 | 0.02 Min | 410 |

| SAE 1010 | 0.08 - 0.13 | 0.30 - 0.60 | 0.030 | 0.030 | 0.02 Min | 430 |

| SAE 1012 | 0.10 - 0.15 | 0.30 - 0.60 | 0.030 | 0.030 | 0.02 Min | 450 |

| SAE 1015 | 0.13 - 0.18 | 0.30 - 0.60 | 0.030 | 0.030 | 0.02 Min | 470 |

| SAE 1018 | 0.15 - 0.20 | 0.60 - 0.90 | 0.030 | 0.030 | 0.02 Min | 510 |

| SAE 1020 | 0.18 - 0.23 | 0.30 - 0.60 | 0.030 | 0.030 | 0.02 Min | 570 |

| SAE 1022 | 0.18 - 0.23 | 0.70 - 0.90 | 0.030 | 0.030 | 0.02 Min | 600 |

| SAE 1025 | 0.22 - 0.28 | 0.30 - 0.60 | 0.030 | 0.030 | 0.02 Min | 600 |

| Note: All the grades are Al killed. | ||||||

| Any specific chemistry requirement can be mutually discussed & agreed. | ||||||

| Medium Carbon Grades (5.5 to 16 mm Dia ) | |||||||

|---|---|---|---|---|---|---|---|

| Grade | %C | %Mn | %Si | %P(Max) | %S (Max) | %Cr | UTS (MPa) |

| En8D/45C8 - IS7283 | 0.40 - 0.45 | 0.70 - 0.90 | 0.15 - 0.30 | 0.025 | 0.025 | 0.10 - 0.30 | 610 min |

| En8A | 0.33 - 0.38 | 0.70 - 0.90 | 0.15 - 0.30 | 0.025 | 0.025 | 0.10 - 0.30 | 580 min |

| Any specific chemistry requirement can be mutually discussed & agreed if Feasible | |||||||

| Ball Bearing Grade (5.5 to 16 mm dia.) | ||||||

|---|---|---|---|---|---|---|

| Grade | %C | %Mn | %P(Max) | %S (Max) | %Si | %Cr |

| En31 | 0.90 - 1.20 | 0.30 - 0.75 | 0.025 | 0.025 | 0.10 - 0.35 | 1.10 - 1.60 |

| High Carbon Grades (5.5 mm to 16 mm Dia ) | ||||||

|---|---|---|---|---|---|---|

| Grade | %C | %Mn | %Si | %P (Max) | %S (Max) | %Cr (Max) |

| HC38B / SWRH38B | 0.35-0.40 | 0.60-0.90 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| HC42B / SWRH42B | 0.40-0.45 | 0.60-0.90 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| HC48B / SWRH48B | 0.45-0.50 | 0.60-0.90 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| HC52B / SWRH52B | 0.50-0.55 | 0.60-0.90 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| HC58B / SWRH58B | 0.55-0.60 | 0.60-0.90 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| HC62B / SWRH62B | 0.60-0.65 | 0.60-0.90 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| HC68B / SWRH68B | 0.65-0.70 | 0.60-0.90 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| HC72B / SWRH72B | 0.70-0.75 | 0.60-0.90 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| HC78B / SWRH78B | 0.75-0.80 | 0.60-0.90 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| HC78BCr / SWRH78BCr | 0.75-0.80 | 0.60-0.90 | 0.15-0.30 | 0.030 | 0.025 | 0.25 |

| HC82B / SWRH82B | 0.80-0.85 | 0.60-0.90 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| HC82BXHMn | 0.80-0.85 | 0.70-0.90 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| HC80BCr (PC) / HC80B | 0.78-0.83 | 0.60-0.90 | 0.15-0.30 | 0.030 | 0.025 | 0.20 |

| HC82BCr (LRPC) / SWRH82BCr | 0.80-0.85 | 0.60-0.90 | 0.15-0.30 | 0.030 | 0.025 | 0.30 |

| HC88B | 0.85-0.90 | 0.60-0.90 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| HC42A / SWRH42A | 0.40-0.45 | 0.30-0.60 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| HC52A / SWRH52A | 0.50-0.55 | 0.30-0.60 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| HC62A / SWRH62A | 0.60-0.65 | 0.30-0.60 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| HC68A / SWRH68A | 0.65-0.70 | 0.30-0.60 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| HC72A / SWRH72A | 0.70-0.75 | 0.30-0.60 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| HC78A / SWRH78A | 0.75-0.80 | 0.30-0.60 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| HC82A / SWRH82A | 0.80-0.85 | 0.30-0.60 | 0.15-0.30 | 0.030 | 0.025 | 0.10 |

| Note: All High Carbon grades are Si killed, | ||||||

| Any specific Chemical & Mechanical property requirements can be mutually discussed & agreed. | ||||||

| Special Electrode Wire Grade (5.5 mm dia.) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Grade | %C | %Mn | %P(Max) | %S (Max) | %Si | N2 PPM | UTS (MPa) | %RA |

| CO2 | 0.06-0.10 | 1.40-1.60 | 0.030 | 0.025 | 0.80 min | 70 max | 540 max | 75 min |